Advanced Beyer-Garratt built in Australia

Richard Stuart has built free lance "ride

in" Beyer-Garratt for 7.25" gauge.

Coal fired with many advanced

features

Updated July 10th 2004

Richard's wife demonstrating the driving position

Hinged tanks to access the engines

The assembled LemPor exhaust Nozzle

Detail Components of the exhaust

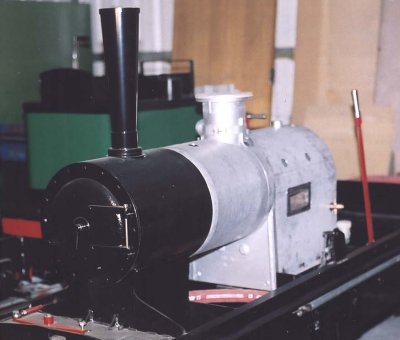

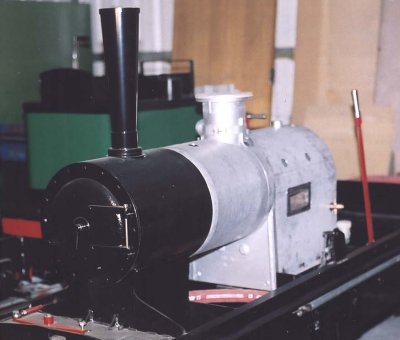

Boiler mounted on cradle

Drivers view of the "office"

Note reversing linkage for front engine

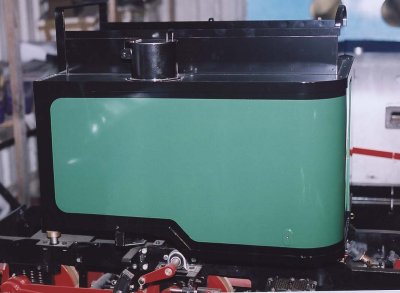

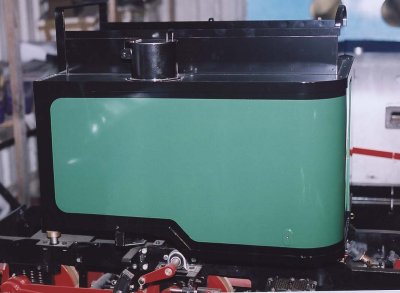

Rear Tank

Water valves

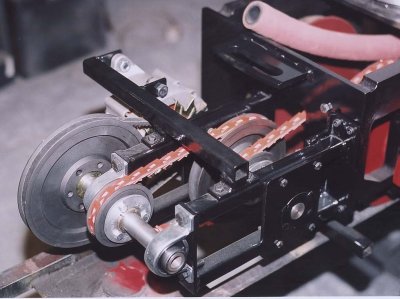

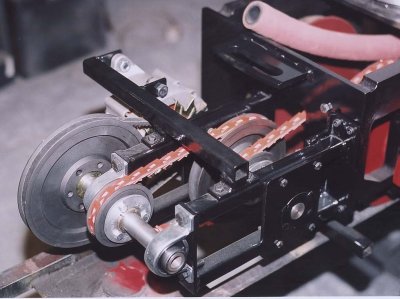

Alternator

Alternator drive mechanism

Boiler with partial cladding, note "slots" in

the side of the firebox for the Superheaters to cross over the fire .

Painted rear tank

January 26th 2004

January 26th 2004

Of the two levers on the RH side of the cab. The outer

lever is the reverser, the inner is the throttle.

First Steaming

First Steaming, June 2004

First Run!

The following sequence of photo's were taken at the

Castledare track in Perth, Western Australia on Saturday July 10th 2004 by

Russell Dunn

Lighting up for the first run July 10th 2004 Yep she is

coal fired......

The arrangement for the valves shown here is described

by Richard below.

Immediately downstream of the dome is an air

operated, fail closed, shutdown valve. It opens automatically when

the regulator is first cracked open, via a micro-switch on the regulator handle which

operates the air supply via a solenoid valve. An emergency

shutdown valve is part of my oil industry culture, and the philosophy is

to be able to isolate the pressure as close as possible to the source.

The electrics which operate the solenoid valve are controlled by a key

switch. There cannot be many steam locos which need an ignition

key to make them go.

The main regulator valve is downstream of

the Superheater and mechanically controlled by the regulator

handle. The regulator valve itself is partially hidden behind the

reversing lever.

The blower steam diverter valve is mounted

on the side of the boiler below the dome. When the regulator is

closed, blower steam is diverted through the Superheater element.

The theory is that the blower steam helps to keep the Superheater

cooled. The diverter valve is air operated and controlled by the

same microswitch and solenoid valve as the shutdown valve. When

the regulator is open, the blower steam is diverted directly to the

blower nozzles in the usual manner.

The drain cocks are also air operated and

controlled via an electrical switch in the cab and another solenoid

valve.

The alternator field coil is energised by a

microswitch attached to the reversing lever. The alternator is

only electrically energised when the loco is in forward gear (I don't

know if alternators work when spinning in reverse).

Time will tell whether these complications

are a useful innovation or unreliable nuisance. I still need to do

a few finishing off tasks before the Garratt can be put into passenger service

at Castledare.

Richards wife has a turn.....

The inspiration!

|